Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

- Icing Platform?

- Indiana Harbor Belt abides

- Freezing haze

- Corrections (for those who care)

- C&NW at Nelson

- Fallen Flags

- A dangerous job made worse

- Water Stop

- Passenger trains have right of way over freights?

- Coal

- Never ceases to amaze me.

- Still chuggin' (in model form)

- Great shot

- Westerly Breeze

- For the men, a trapeze

- Tickled

- Sense of loneliness ...

- 2 cents

- Charm City

- What an Outrage

- Brighton Park

Print Emporium

Full Steam Ahead: 1913

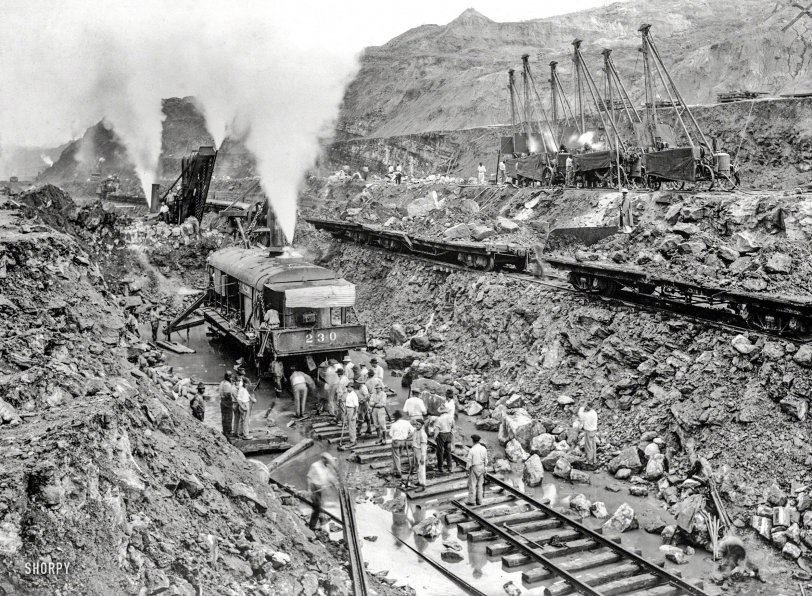

"Panama Canal excavation, 1913." The world's most celebrated shortcut marks its centennial this month. Copy negative; Harris & Ewing glass plate. View full size.

Moving the shovel

Beside winding up with a very useful canal, this operation showed the way to large open pit mining that followed in places like Utah and Minnesota. The same equipment was used there.

The shovels are steam operated and move on railroad track. There are outriggers near the front to stabilize the shovel while digging. On this type of shovel only the boom swings to load the railroad cars. The same railroad that took the rock away also delivered coal and water to the shovels and drills. In normal digging the shovel was supported on short panels of track, about 10 feet long. As the shovel dug its way forward a track gang would leap frog the panels from the rear of the shovel to the front. I can't tell for sure who made these particular shovels but the shovels used for the canal were made by the Bucyrus and Marion companies. Both made similar machines. It appears in the picture that they are laying track to back the first shovel out of the cut to get it out of the way of the other shovel and prepare for the next blast.

The machines on the bench above the trains are drills, drilling holes in the rock for the next blast. Before the blast can take place, both shovels have to be moved out and the tracks have to be removed. Then the holes can be filled with that new fangled dynamite and the rock can be blasted, the rail re-laid, and the shovels moved back in to start digging.

The railroad track was also probably panels to speed up assembly and disassembly, sort of like Lionel track. A crane would come along and lift out 39 ft long panels, ties and all, and put them on a flat car behind it. The process would be repeated in reverse to lay new track. The railroad cars are flat cars with a bulkhead on one side. At the dump where they are unloaded a lever is swung into the first car from the side. As the train moves the lever pries the rock out of the cars to the open side. In later operations, side dump cars were used where the car bed itself was tilted to the side with air cylinders to dump the load.

It was very labor intensive, dangerous, hard work to do these things, especially in the tropical heat. Hats off to these guys.

Blast Hole Drills

Here is a beautiful restoration of a similar blast hole drill, although this one is run by a gas engine, instead of piped in steam or air...

On Shorpy:

Today’s Top 5