Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Tough Guys

- Lost in Toyland

- And without gloves

- If I were a blindfolded time traveler

- Smoke Consumer Also Cooks

- Oh that stove!

- Possibly still there?

- What?!?

- $100 Reward

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

- Icing Platform?

- Indiana Harbor Belt abides

- Freezing haze

- Corrections (for those who care)

- C&NW at Nelson

- Fallen Flags

- A dangerous job made worse

- Water Stop

- Passenger trains have right of way over freights?

- Coal

- Never ceases to amaze me.

- Still chuggin' (in model form)

Print Emporium

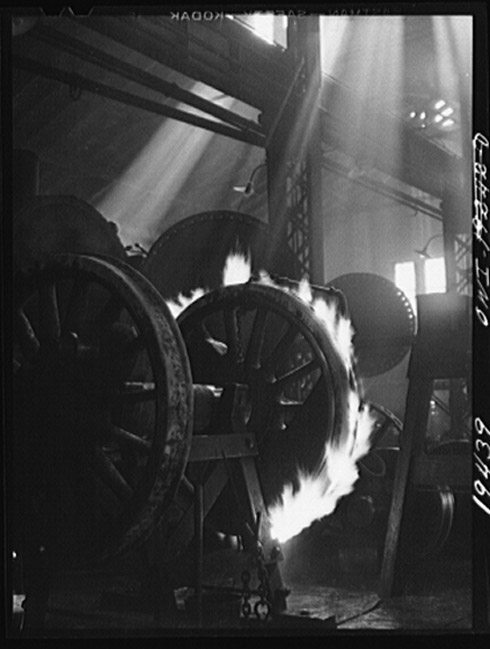

Wheel of Fire: 1943

Re-tiring a locomotive driver wheel in the Atchison, Topeka, & Santa Fe railway shops at Shopton, near Fort Madison, Iowa. March 1943. View full size. 4x5 Kodachrome transparency by Jack Delano.

Ring of Fire explained:

Comments from a friend -

Many's the night I supervised that same operation at Enola Enginehouse machine shop when we sweated new tires onto the P5 wheels. (GG1s had smaller wheels with tires but those were all done at Wilmington.)

The trick was, after the wheel cooled down to room temp. (after removing the tire) you had to measure WITH A MICROMETER, the outside diameter of the wheel to .001 inch. Then you had to measure the inside diameter of the tire also to .001 inch. As if that wasn't difficult enough, if it was cold outside and somebody opened the barn door the tire or wheel could change diameter and blow the entire exercise.

If the tire was too large, we had to choose the correct thickness of shim and insert it between the tire and the wheel while heating the tire with a flame.

Today that is all a lost art. Occasionally we'd get the tire too tight on the wheel and it would snap. Also tires would come loose during service. If the inspector suspected a tire was loose, he'd put a chalk mark across the tire and wheel and watch it when it came back onto the pit and see if the chalk line still matched up.

The P5s and GG1s didn't have dynamic brakes so the enginemen rode the independent brake a lot on the downgrades.

WDV

This process was also known

as "sweating" on a tire.

These series of photos are fantastic!

Fire Wheel

This is an interesting shot but I believe the picture should be rotated 90 degrees clockwise. The heavy steel support illuminated below the flames is a stand that supports the axle and keeps the wheel off the ground. Notice the flames also point to the left (up). Nevertheless, this is a beautiful example of a common maintenance procedure on a steam locomotive. The steel tire is separate from the cast steel wheel center. The inside of the tire is machined several thousandths of an inch smaller than the wheel center. It's heated by fire from a ring of gas pipe. As the tire gets hot, it expands and is then driven onto the cooler wheel center by workmen with sledge hammers. It's then clamped into position and allowed to cool and shrinks tightly on the wheel. Jack Delano's photography captures the essence of railroading of this era with elegance and sensitivity.

[The wheel has been rotated. Below, a clearer view of the procedure. - Dave]

Delano Picts

Did Jack work for the Santa Fe RR, or was he an avid railfan like many of us are especially me? I know you told me that he passed away 10 yrs ago, has his family saved and ever thought of giving his great pictures to Trains & Railfan mags? How were you able to get the photos? I'd like to know more about jack and who he was and how he lived.

Fire Wheel

Great picture would like to see more RR shop pictures

On Shorpy:

Today’s Top 5