Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Baldwin 62303

- Baldwin VO-1000

- Cold

- No expense spared

- Tough Guys

- Lost in Toyland

- And without gloves

- If I were a blindfolded time traveler

- Smoke Consumer Also Cooks

- Oh that stove!

- Possibly still there?

- What?!?

- $100 Reward

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

- Icing Platform?

- Indiana Harbor Belt abides

- Freezing haze

- Corrections (for those who care)

- C&NW at Nelson

- Fallen Flags

- A dangerous job made worse

- Water Stop

Print Emporium

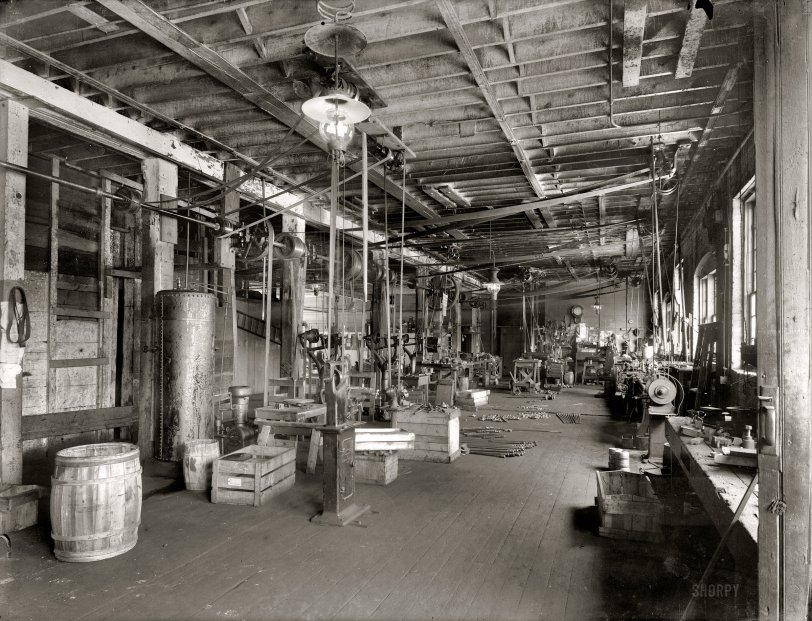

Workshop: 1916

Circa 1916. "Hackett Motor Car Co., Jackson, Michigan." National Photo Company Collection glass negative. View full size. Another view here.

Electricity isn't far behind

Maury Klein has a great book called The Power Makers which describes the race to industrialize using the power of steam (which clearly was the driving force of this shop), the rate at which steam depleted forests and then led to widespread use of anthracite coal, and finally to Edison and Westinghouse's battles to electrify the country.

Highly recommended, a very engaging study of the key decisionmaking and makers behind the US industrial revolution. His description of the mighty Corliss steam engine will make you weep.

Dad's old shop

For many years my dad was a machinist for the NYC Department of Sanitation. I'd visit him at his job in Bed-Stuy. It always had a smell of grease and oil. I loved that smell.

Back in those days the they would burn the trash right on site in these huge furnaces. I remember the shop always being nice and toasty in the winter and hot as hell in the summer.

I always thought it was the neatest place to be.

Under Pressure

That's an an air tank, not a water heater. The compressor is to the right.

Overhead Drive Belts

My father used to work in the Erie RR maintenance shops as a teenager back before WWII. He was telling me one day about all the overhead belt drive machinery. The belts are all leather and apparently making, fitting and adjusting new belts was a skilled trade in those days. He remembers a company that would come in about once a year to inspect, adjust and, if necessary, replace worn belts. This was all tied up with getting the drive gear ratios adjusted properly for each piece of equipment, and the drive wheels placed properly. According to Dad it was not a task you took lightly because an improperly adjusted belt or worse, a broken belt, would have serious consequences.

Re: Belts and shafts...

Actually, you'd be surprised how easily those line shafts could be set up.

Typically the shaft supports had some method of adjustment- quadrant screws, slots, etc. That mad it as simple as bolting the bracket to the board or joist, run the shaft through it, and tweak the screws 'til it's straight.

You can see the adjusters fairly clearly on the left-hand post-mounted shafting, and on the nearest-right ceiling shaft that powers the pedestal grinder.

The pulleys are almost as easy. Yes, they need to be somewhat closely aligned, but they're slightly crowned and typically wider than the belt itself. That and the distance allow them to be misaligned by quite a bit and still work reliably.

Setting the tension was reasonably easy too- cut the belt to length, press in new clips. pin back together, done. If/when the belt stretches or breaks, just cut and add another clip.

It was actually surprisingly efficient for the time.

More on Drive Belts

Drive belts were not prone to come off their pulleys. One of the things we studied in engineering when I went to school was how they worked. The pulleys have a slight crown on them. As the moving belt starts to move sideways off a pulley, the crown causes it to move back. We analyzed the mathematics of the process. The belts are self-centering.

Alignment not-so-critical

AT wrote: "It must have been a job keeping those belts from spinning right of their pulleys. Alignment must have been critical."

Actually, with flat leather belts, the pulley alignment is not a critical factor in their performance. Usually the flat pulley has a slight crown on the surface which helps to keep the belt centered on the pulley. The torque delivered comes strictly from the friction between the flat surface of the belt and the pulley face.

The more modern v-belt requires precisely aligned pulleys because the friction occurs between the edges of the belt and the walls of the pulley grooves into which the belt is forced by drive tension.

Thoroughly Modern Pulley

This appears to be a very modern shop for its time, with the gaslight and the power-driven machines. When I was young we used flat belts like these to power our buzz saw -- we attached it to our John Deere Model A tractor. When those belts broke the result was sometimes tragic.

Wow! OSHA would have a stroke!

Riveted water heater tank, overhead belts, no guards on grinders, parts all over the floor, overhead gas lighting and, I'm sure, open containers of solvents somewhere in the mix. Yassir, 'nuf stuff in there to keep the OSHA inspector busy for days!

Drive belts

It must have been a job keeping those belts from spinning right of their pulleys. Alignment must have been critical. I imagine that there was a trade devoted to that task. And when a belt snaps and flies off there were whoops and hollers! All right, all right. Get back to work.

Mind your fingers

Shops like this one are engineering marvels. The big belts and shafts, the gaslights and machinery all on a safe oil soaked wood floor littered with stock, fascinate me.

Old iron!

Let's see ... Two W.H. & J. Barnes Drilling Machines (or possibly Rockfords, but they don't have back gears) and one of a different model that may be an earlier or smaller version, or a different brand entirely.

The near machine is a Rockford (no relation) No. 3 hand miller, and the small pedestal grinder just past it is, I think, a Buffalo Forge- the work rests are sitting on the crate in front of it.

I think the shaper is a Gould & Eberhard 16", but I'm probably wrong. Can't see enough of either lathe for an ID, but the horizontal mill toward the back right is almost certainly a small Brown & Sharpe.

All that and some gas lamps, too!

On Shorpy:

Today’s Top 5