Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Details, Details

- What's that building to the left of the tower?

- Coal Barges

- Bromo-Seltzer

- Inner harbor

- The Basin

- What a headache!

- Giant stepladder?

- Baldwin 62303

- Baldwin VO-1000

- Cold

- No expense spared

- Tough Guys

- Lost in Toyland

- And without gloves

- If I were a blindfolded time traveler

- Smoke Consumer Also Cooks

- Oh that stove!

- Possibly still there?

- What?!?

- $100 Reward

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

Print Emporium

Loaf Wrappers: 1914

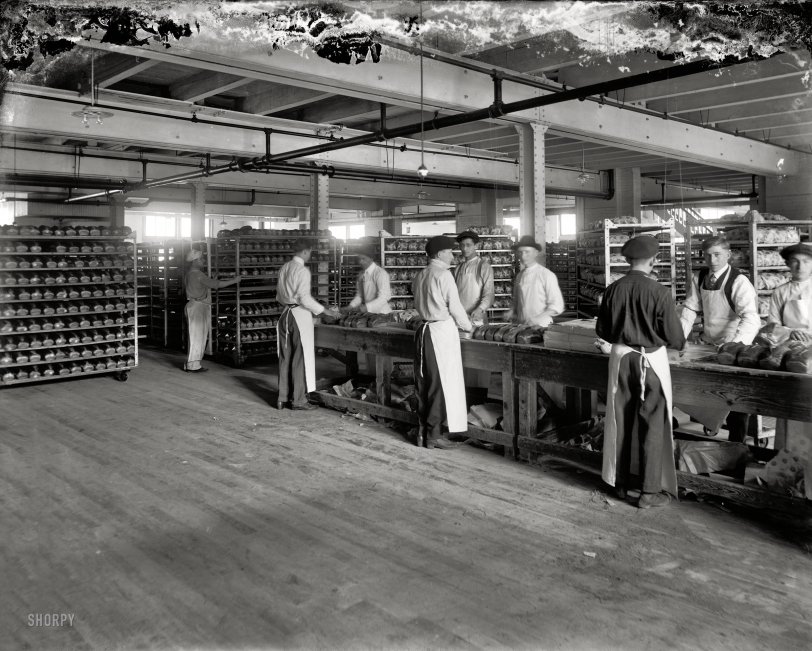

June 6, 1914. "Shipping and wrapping room, Gordon Pagel Baking Co., Detroit." 8x10 inch dry plate glass negative, Detroit Publishing Co. View full size.

Piece of cake

My mother-in-law (who died in 1997) was born in 1913. She grew up on a farm in Minnesota, and her mother made bread for the large brood (8 kids, I think) daily. On the rare occasion that they got to have store-bought bread from in town, she she said was it was a MAJOR treat because it was like having CAKE!

Shining Light on the Mold

The lighting is from an interesting period of time. Unprotected incandescent bulbs in what were probably gaslight fixtures. Not a sign of a flourescent bulb or fixture yet.

The lights probably helped them see any of the mold that fell from the top of the ceiling (well, top of the picture anyway). ;-)

I get the impression that the gent on the right looking at the camera is someone who wanted to get in the picture but doesn't work that line. He's not wearing a hat, is wearing a vest over his shirt, and seems more eager than anyone else to be there. It almost seems like some of the other fellows are thinking "Look at that ham, coming here just to pose in the picture!"

[I guess "flour"-escent bulbs would lend themselves to bakery use. - Dave]

Polka Dot Loaves

You are absolutely correct, Michaeljy. That bread you can squeeze into a ball the size of a quarter, then pop it in your mouth. 80% air.

Gordon-Pagel Bread Company

History and Biography,

The City of Detroit and Wayne County, Michigan,

1908.The Gordon-Pagel Bread Company

…

An inspection of the plant of the Gordon-Pagel Bread Company, the most modern in the city, can not but compel the observer to recognize that baker's bread may be made thoroughly wholesome and more palatable than is the average domestic product. The absolute cleanliness of the establishment in every department and the strict regard to modern sanitary precautions and provisions, together with the scientific methods employed in the treatment of the materials used, proves a revelation to one who has not previously familiarized himself with the workings of baking establishments of the highest type.In 1900 James C. Gordon and William M. Pagel entered into partnership, under the title of Gordon & Pagel, and forthwith established the business which has already grown to be one of the most successful of the kind in the city of Detroit. Mr. Gordon had previously passed about twelve years in the employ of the Morton Baking Company, of this city, and brought to bear in the new enterprise a most thorough experience of a technical order, and Mr. Pagel had conducted a successful retail grocery business for about a decade prior to entering into partnership with Mr. Gordon. The original plant of the firm occupied a small section of the present ample quarters, at the corner of Chene and Hendricks streets, and at the start only two men were employed in the baking department. … On the southeast corner of the same streets they erected in 1907 a modern stable building, one hundred by sixty feet in dimensions, and this is utilized for the accommodation of their fifty or more horses used in connection with the delivery department of the business. The attractive wagons used in this department number about thirty at the time of this writing.

…

A brief description of the modus operandi of a modern baking plant can not be malapropos in this connection. The first operation is the sifting of the flour, followed by the blending of the winter and spring wheat varieties; next the flour, weighed to exact proportions, is placed in a mixer, with an equally definite amount of sterilized water, which is heated to the proper temperature indicated by science and experience, which also determine the blending of the two varieties of flour. After the dough is thus prepared in the mixer it is placed in large wooden troughs, scrupulously clean, and later into a machine which weighs with exactitude the amount to be placed in each loaf. This small portion is then run through a kneading machine and shaped for the baking pans, which are then sent to the proving room. The scientific appliances and facilities of this room afford means of obtaining results not possible in the home, and the even temperature maintained insures uniform size and also symmetry in the loaves of bread. From the proving room the waiting loaves are taken to the baking oven, whence is finally turned out the completed product, ready for the consumer and far superior to that secured by old-time methods, according to which chance, unequal temperature, unproven and unequalized grades of flour and inexact proportions gave ever varying results.

…

Elsewhere on Shorpy: Gordon & Pagel Stables, photographed the same year.

Wonder Bread

Used to have polka-dot wrappers similar to those, didn't they?

Not a nickel anymore

Seeing this photo got my bread cravings started so I went to a local bakery. And I was able to purchase two loaves fresh from the oven. All I had to do was take out a small title loan on my car.

Getting Paid to Loaf

This brings to my mind the Abbott and Costello bit about getting paid to loaf, another one of their classics.

Cleanliness

Someone remarked about the debris under the worktables. This does not surprise me. I'm sure that was cleaned up at the finish of the work day. If you look around, you see that the rest of the floor is very tidy.

Wish

we could "like" comments.

In my case, I "like" Cracker's comment "The greatest thing since before sliced bread."

Waxing nostalgic

Kids today don't know what they are missing by not having a waxed paper wrapper to take to the park with them. It worked great on the slides. Put the paper down, sit on it, and push off down the slide. Seemed like you could shoot half way across the park after using it. Very slick.

Real Bread

I cannot pinpoint exactly when freshly baked bread went from being substantial, tasty and marvelously textured to becoming airy, tasteless and Kleenex-like. Personally I'm guessing plastic wrappers and mass quantity production caused it all to become the boring fluff loaves being sold today by the ton by commercial bakeries who have put many, if not all of the small, individual bakeries out of business. These old time privately owned bake shops that made their signature varieties daily in small towns and cities across America used paper bags (or the waxed paper & cellophane wrappers like these in the picture) and old ovens that created crusty, crunchy outsides and delicious, full bodied, yeasty, buttery, and often, hot out of the oven seeded kaiser rolls, golden brown challa breads, baguettes of all nations, breads that were truly the staff and stuff of life. The bland uniformity of most of the bread available now just leaves me without any gustatory enthusiasm.

On the One Hand

On the one hand, these workers aren't wearing any plastic gloves or hair nets (hats work well in place of hair nets) in the interest of being sanitary.

[On the one hand is a funny place to wear a hair net. Had to say that. - Dave]

On the other hand the bread is free from the preservatives we now have and the grain this bread is made from is free from modern pesticides, a hundred years of over-farmed soil and modified genomes.

One of the things I wish I could time travel for is just to taste the food from earlier ages. Did it REALLY taste better?

Automation

So this image basically captures the bread manufacturing process at a point where the actual making of the bread was mechanized, but the slicing and wrapping wasn't. Looks like waxed paper they're wrapped in, which was still the norm when I was a kid in the 1950's. The modern cellophane inner wrap and plastic outer bag are a real godsend for freshness.

Wrappers

You don't like to think about what was getting on these loaves at this stage in the process.

Wrapped loaves

The greatest thing since before sliced bread.

That's a wrap!

I think this picture should be called D'oh boys! Sorry, bad pun. I also can't help but wonder how many of these dough boys became doughboys in WWI?

I wonder --

"How people would like it if we sliced it before it went into the bag?"

The Floor

Take a look at the floor and the trash under the bench. Looks like party-city for rats and insects.

The Wrappers

I remember when food companies used the term "Untouched by human hands." The punch line had something to do with monkeys.

On Shorpy:

Today’s Top 5