Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Details, Details

- What's that building to the left of the tower?

- Coal Barges

- Bromo-Seltzer

- Inner harbor

- The Basin

- What a headache!

- Giant stepladder?

- Baldwin 62303

- Baldwin VO-1000

- Cold

- No expense spared

- Tough Guys

- Lost in Toyland

- And without gloves

- If I were a blindfolded time traveler

- Smoke Consumer Also Cooks

- Oh that stove!

- Possibly still there?

- What?!?

- $100 Reward

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

Print Emporium

Sweater Set: 1942

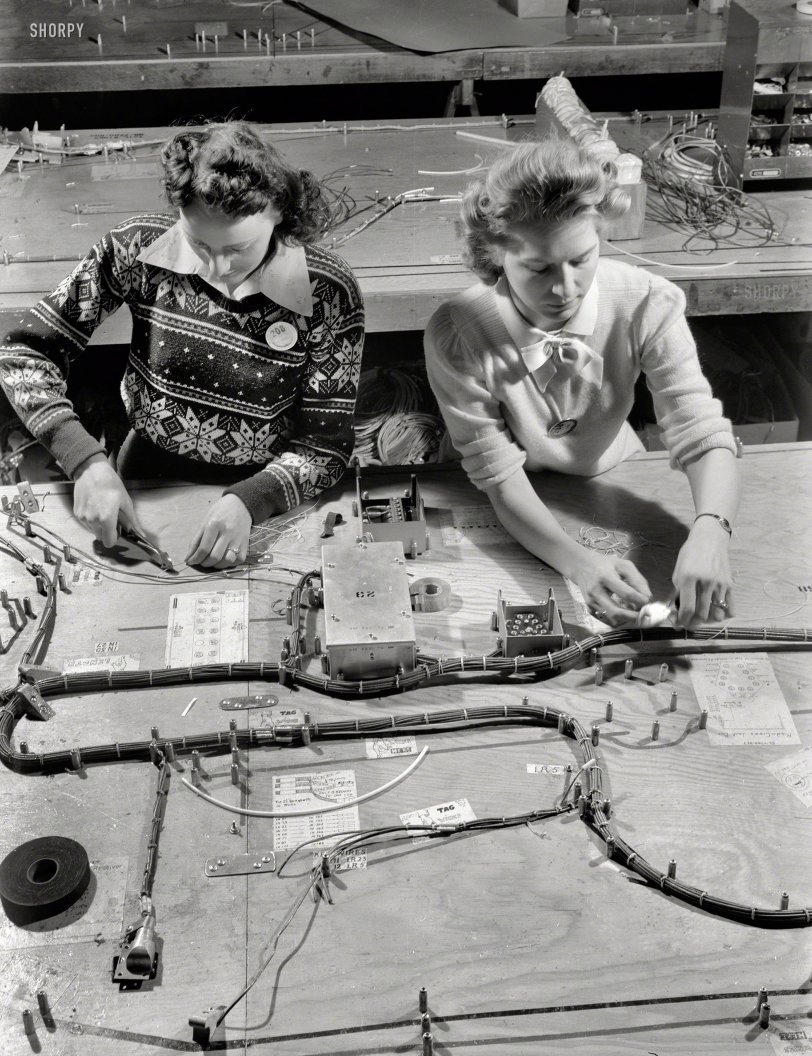

December 1942. "Boeing aircraft plant, Seattle. Production of B-17 'Flying Fortress' bombers. Routing and labeling electrical wires on template prior to installation." Photo by Andreas Feininger, Office of War Information. View full size.

You can probably still see this in the 787 factory

As StefanJ noted, this is still done today. There is a little bit of automation - the individual wires are often cut to length by machine before they are bundled, and some wires get connectors installed on them by machine. But the bundling part still looks like this. More than one company sells the clips, pegs, clamps, and other hardware you need to make boards like this. (They even sell the cutters that round off the ends of the tie-wraps, but a lot of places cheap out and just use wire cutters, which makes tiny plastic daggers that are ready to rip your skin.)

One thing that probably was automated, even when this picture was taken, was harness testing. After these ladies were done, the harness was connected to a machine that applied current to one wire at a time. It made sure that it could see current on the other end of that wire, and no place else; if the harness failed the test, a red light would go on and the harness would be sent for rework. A company here in Kansas City still makes the testing equipment for this.

Some wires may have been "hi-pot" tested, where a voltage much higher than the wire would usually see in service would be applied, to check for insulation damage. This might have been another manual operation at the time the photo was taken; later on it was incorporated into the automated harness testing.

Carey Built My Pinto

Every time I put my 1974 Pinto into reverse, I blew the fuse that protected the circuit powering the radio, backup light, and turn signals. I blame Carey for missing his part of the wiring harness.

Reach Out and Touch Someone

Western Electric had factories full of people doing that for central office crossbar switches as recently as the 70s.

A robot drifted in near the end, but caring for the robot was pretty labor intensive too, and then crossbar switches disappeared anyway.

I think the plant is a healthcare center now.

They still do it like that.

Building wire harnesses on flat templates, that is.

And mechanics all over the world still prefer their wire harnesses being tied up with lacing cord instead of those fancy plastic tie-wraps. No flesh hooks, you know, from poorly cut-off tie-wrap tails.

However, tie-wraps win on the economic side, and it is a lot easier to start with the tiew-wraps loose for final adjustments, and then tightening them up one by one.

B-17s vs. Ford Pintos

Those women are making what's known as a wiring harness. The pegs on the board route the wires in the same lengths and directions they'll be when the harness is installed in the aircraft it's intended for.

I spent several months in my youth working on a factory assembly line making similar wiring harnesses for Ford Pintos. But instead of two people who no doubt underwent some training in how to build that wiring harness, I was just one of 20 or so who knew how to put one piece of the harness on as it went gliding past me. If I missed one -- Oh well, some new car owner was going to have problems with his headlights, or the heater fan, or something.

I think the repair history of B-17s and Pintos probably says something about how to manufacture a wiring harness.

We have never seen the like

Of the airmen flying B-17's and 24's on daylight raids over Germany

during the first half of the war. It was the most dangerous place to be at that

time as the Messerschmitts and Focke-Wulfs shot them down like the

sitting ducks they were. The toll was horrific: until we developed fighters

that could escort them out and back. So,these Ladies were a part of so many

American workers who could build these bombers faster than the Germans could shoot them down.

On Shorpy:

Today’s Top 5