Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Ticket Retention

- Killed by Amtrak

- Back to the Future

- Heckuva remote control!

- Sometimes — Things Go Bump!

- I SEE THE LIGHT

- Union Switch and Signal Company

- Get That Light Out Of My Eyes

- Eggs. Eggs. Eggs. The Egg Man is Here!

- Foreboding caption

- Famous Hollywood faces

- Not just S&P

- re: Those things in the jar

- Up In Smoke

- Medical Smoking

- Quick fix

- A Quink Comment

- If You’re Like Me, Never

- Delivering the News

- U.S.A.

- S&P

- 1940 Zenith radio model 6G601

- Quality goes in before the name goes on!

- Snazzy skirt

- Carbon Arc Lamps

- Illuminate us

- I remember it well

- I can't prove it

- Complicated then, forgotten now

- Bryan-Stevenson

Print Emporium

A Chorus Line: 1905

Lake Erie circa 1905. "Hulett clamshell hoists, Cleveland, Ohio." 8x10 inch dry plate glass negative, Detroit Publishing Company. View full size.

What's up dock?

Since 1858, gravity has been used to load ore boats (naval tradition notwithstanding, all bulk carriers are "boats" on the Great Lakes) from structures properly known as "ore docks."

The system was introduced at Marquette, Michigan. Ore was delivered to the top of the dock, and dumped into large holding pockets, each fitted with a side discharge chute. Brigantine-rigged (no boom between masts) Schooners were the favorite for ore shipments. They came alongside and typically loaded ore directly on deck, roughly 300 tons per trip — which could take four or more days to offload by hand on arrival, longer if it was loaded in the holds below deck

As demand for ore skyrocketed, deck hatches were cut into these vessels to increase capacity. The first bulk freighter (the R.J. Hackett) was purpose-built for the iron ore trade in 1869. These bigger vessels opened the floodgates to a variety of mechanical unloaders mentioned in the earlier post, but the Brown and Hulett machines emerged as the leaders.

A Brown bucket held roughly 1-1/2 tons, but the machine could only lower and raise the bucket straight into the hold, where it still had to be filled by hand; fitting the machine shown with clamshells should have greatly improved its efficiency.

The first Hulett bucket held 10 tons (later models could handle up to 22 tons per bite), but its greatest advantage was its mobility, as it could move up & down, left & right and forward/reverse within the hold, greatly reducing the hand shoveling.

Lakes boats didn't come home to Michigan empty, they typically backhauled coal, which was also loaded by gravity.

I count 11 also

I also count 11 including the man bent over behind the crane rails near the steam vent and the 3 atop the rail cars

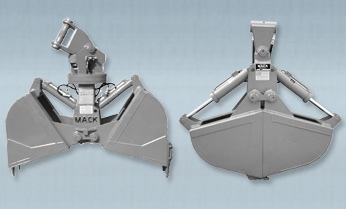

Hulett Clamshells

These are Brown rigs with Hulett clamshells, as noted in the caption, for transferring ore onto railcars from ships called ore carriers.

Brown Fast Plants

Tracking down the historical/technical details of this photo was complicated because the internetz are full of information on its more famous kin: the still-standing Hulett Ore Unloaders.

Nonetheless, the best information on the pictured machinery is in the 1905 book, "Brownhoist": Patent Automatic Hoisting and Conveying Appliances. Pages 43 & 44 have alternate views of the same equipment.

Briefly: The location is the Cleveland & Pittsburgh Dock of the Pennsylvania railroad. This type of hoist, designed by Alexander Brown, was known as a "fast plant" and was used to unload ore from a ship and transfer it to waiting rail cars. The specimens here were all steam-powered but later models used electricity. The unloading arm of the hoists spanned 5 to 7 railroad tracks and could load fifty rail cars without shifting. The business end of the hoists were equipped with Hulett clamshells and Andrews scrapers.

Clamshells

Technically, clamshell hoists are so named because they (somewhat) resemble and open and close similarly to the bivalves' shells.

Two guys with great proprioception

And they give you a sense of the huge size of this processing plant. I wonder how many men got injured falling off the hoists, working up there in various drenching conditions?

How exactly did these hoists work? They would lift up nets or pallets full of oysters, which would then be trundled out by conveyor belt? The din and smell of a fleet of ten boats unloading at one time must have been stupefying. Do you have any shots of this plant at work?

[Clamshell hoists don't have anything to do with oysters, clams, or seafood in general. They're for loading iron ore. - Dave]

Count the People

I stopped counting at eight people, upon encountering an additional one that I couldn't tell about.

Nine men...

...one must look hard to find most of them.

On Shorpy:

Today’s Top 5