Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Baldwin 62303

- Baldwin VO-1000

- Cold

- No expense spared

- Tough Guys

- Lost in Toyland

- And without gloves

- If I were a blindfolded time traveler

- Smoke Consumer Also Cooks

- Oh that stove!

- Possibly still there?

- What?!?

- $100 Reward

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

- Icing Platform?

- Indiana Harbor Belt abides

- Freezing haze

- Corrections (for those who care)

- C&NW at Nelson

- Fallen Flags

- A dangerous job made worse

- Water Stop

Print Emporium

Jiffy Lube: 1904

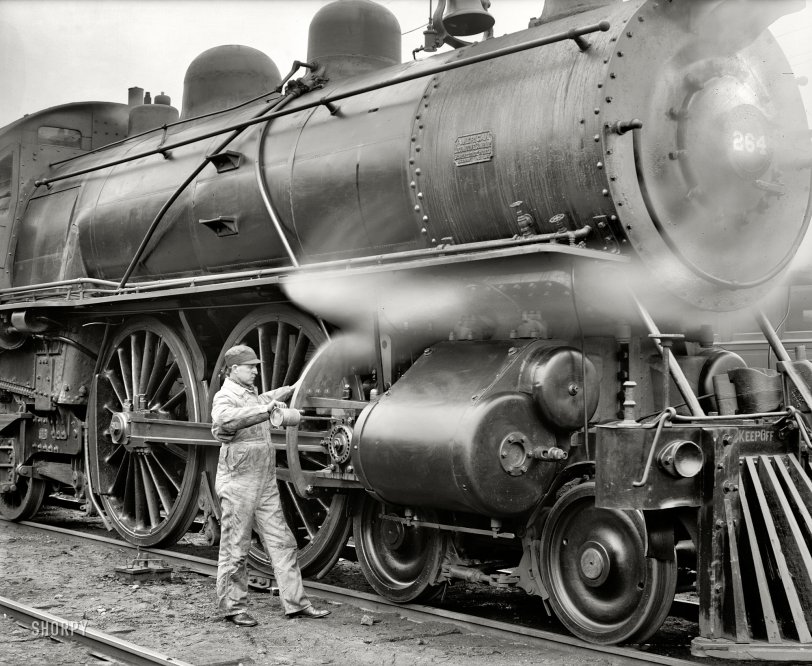

Circa 1904. "Michigan Central Railroad. Oiling up before the start." 8x10 inch dry plate glass negative, Detroit Publishing Company. View full size.

Alumni

Did anyone notice this beauty was produced here in Schenectady NY? The General Electric Alco works, produced some of the finest and biggest locomotive engines ever to run the rails. Sadly, Alco is being demolished for condos, and only a few of these magnificent steamers still ply the rails.

Snappy shoes!

Hmmm.. that oiler is wearing what appears to be a sharp-looking pair of dress shoes. A little surprising considering the working environment!

I have no choice!

I had to chime in on the discussion about all the "pipes", seeing as I am employed as a rail road "Pipefitter" Lol!

1. It is for sand

2. It's still used

3. Yes, it has to be bone dry because they still constantly clog.

Percolator Dome

Now, out of which pipe do you get the fresh-brewed coffee?

The other dome

The other dome is the steam dome. What you actually see is just a cover.

The throttle is located inside of the steam dome. There is also a Dry pipe to the turret located inside of the steam dome.

The reason for the dome is to allow dry steam to exit the boiler.

Bactrian Locomotive

There are two domes because this is a Bactrian Locomotive, not a Dromedary locomotive!

The other dome is known as the Steam Dome. Inside this dome is a pipe which collects the steam made by the boiler and is eventually sent to the pistons to power the locomotive. The dome puts the steam pipe as far away as possible from the boiling waters below so that only steam, not water, gets into the steam pipe. Water, being incompressible, will break the pistons or cylinder covers.

Throttled

The dome behind the sand dome is the steam dome which contains the throttle. Immediately behind that is the auxiliary steam dome which has the whistle, safety valves and most likely a dry pipe for the turret in the cab which supplies steam to the appliances.

The other dome

The dome behind the sand dome is the "steam dome". That is where te steam is drawn from the boiler. If it was lower on the boiler there is more of a chance of picking up water instead of steam which would not be good.

You can see the steps on the side of the boiler below the sand dome. They are there because this was somewhere that needed to be serviced (filled) often.

Two domes

Must mean it's a lady locomotive.

Domes a plenty

The other dome behind the sand dome is the steam dome. It was where the steam was "gathered" prior to being sent to the cylinders. Most all horizontal boilers on trains and traction engines have steam domes. Vertical boilers typically don't need steam domes.

D'Udder Dome

The rear dome is called the Steam Dome. It is the highest point of the boiler and is where the throttle valve is located. Taking the steam from here keeps water from going into the "Dry Pipe" and hence into the steam cylinders up front.

Domes Galore.

The front dome is for sand, as mentioned in several posts. The Engineer pulls a lever in the cab, the rod of which is seen, and this moves a plate beneath the sand in the sand dome until holes line up above the outlets to the pipes leading to the front or rear drivers.

There is another handle in the cab which admits compressed air front or back to force sand down the pipes to the wheels, their control air pipes also visible at the base of the sand dome.

There usually is a round recessed lid on top of the sand dome with a recessed hand hold, secured with a length of chain within the dome cavity, where sand is poured in on the shop track when servicing the locomotive between runs.

Two little steps can be seen bolted on to the boiler side to access the sand dome, bell etc.

The heat of the boiler keeps the sand dry and 'fluid' if rain does get in.

Coal and water would be added to the tender at the same time, and the cab supplies such as oils for lubrication, grease for some bearings, and lamp oil for the various lamps on the engine.

This engine does not yet appear to have a steam-operated electric dynamo nor an electric headlight. It may have an Acetylene headlight?

The second dome along the boiler-top from the front is the Steam Dome.

Within it's sleek casing is a heavy flat-topped dome on top of the boiler proper which houses the steam throttle valve above the water level in the boiler.

The throttle valve is opened and closed thru a rod which passes thru a gland with packing against the boiler pressure to the Engineer's throttle handle in the cab.

Moving his handle lifts and lowers the balanced throttle valve in the steam dome, admitting steam to the cylinders.

On top of the steam dome proper there is a round heavy metal plate bolted down with a steam-tight fit which can be removed when the engine is cold to access the interior of the boiler and the throttle valve.

The third dome from the front is called a 'pop dome' and on top of it can be seen pressure safety valves, 2 in this case. These valves, when both are open, MUST be able to pass more steam than the boiler and firebox can produce under all firing conditions.

One safety valve opens, usually, 3 to 5 pounds sooner than the second.

The vertical round cylinder just ahead of the cab roof, but behind the safety valves is the whistle.

The bell ahead of the sand dome is air-operated on it's right side, the small air pipe visible. The left side of the bell has a rope so the bell can also be 'rung' by the fireman on the locomotive's left.

Dome, De Dome Dome

The dome behind the sand dome is the steam dome, where the throttle valve is located to allow steam to enter the clyinders through internal piping in the boiler. The next open dome area is where the whistle and poppet valve (pressure relief valve) is to allow excess steam pressure out.

Whipped cream would be nice, but...

That second dome is the steam dome. As the water in the boiler boils, steam is withdrawn from the steam dome, which allows pickup of the steam from a point which is always above the water level.

The other dome

That's the one for whipped cream. Sorry; I couldn't not get into this comment thread.

That other dome...

That's the steam dome. It contains the opening to the main steam pipe and its purpose is to allow this opening to be kept well above the water level in the boiler. This arrangement acts as a simple steam separator and minimizes the risk that water will be carried over to the cylinders where it might cause a hydraulic lock - this is also known as priming.

When starting a steam loco, before you start to move, you open the cylinder drain cocks to get any condensate out of the cylinders.

As far as keeping the sand dry, that's one of the reasons for putting the sand dome where it is, boiler heat helps keep it dry. The sand is pushed through the sand pipes by compressed air, and in the example you can see the air connections and valves where they enter the dome. Sand was dried and stored in steam heated "sand houses" before being loaded to the locos.

Nowadays, AC traction control has helped immensely, but sanding, and knowing when to sand is still needed.

That Other Dome...

The rear dome is the steam dome, where the steam collects before it is piped into the cylinders.

Enough with the pipes already!

The two pipes coming from the sand dome are for SAND! One for forward and one for reverse. The lever from the cab to the dome is for turning on and off the flow of sand. Perhaps out of sight behind the trailing truck is a rail washer because leaving the grit on the rails after it's needed causes friction and unnecessary wear on the wheels of the rest of the train.

The small pipe in front of the valve chest is for oil from the hydrostatic lubricator in the cab.

What I don't see if a boiler check or a line from the injector to feed the water to the boiler. I don't see it on the color photo either.

The Rules of Attraction

If anything at Shorpy attracts (pun intended) more attention than a pretty girl, it has to be a railroad engine!

Dome, de dome, dome

Now that we have solved the sand dome mystery including the pipes, valves, and control linkage what is the pupose of the other dome beside or behind it?

A Question

Do any of you fellows know what that pipe behind the driving wheel might be for. Sand, perhaps? Whipped cream?

Give Me a Brake!

It is worth noting that the four wheels of the leading truck have brake shoes to assist in stopping the train, or just the locomotive when operating alone travelling to from it's train.

If there is rain, grease, oil, grass or frost on the rail head, a steam locomotive can be VERY difficult to control, thats where the sand comes in to play.

If the rail is 'bad', an Engineer will often apply sand just before the train stops so there will be sand beneath all the driving wheels for starting.

It appears the front coupler is of a folding-up design and is lying on top of the pilot beam.

The Engineer has poked the spout of his oiler into the hole provided for the purpose and is oiling the wrist pin within the crosshead on the front of the main rod that connects the crosshead with the crankpin on the rear driver.

The crosshead and main rod convert the reciprical motion of the pistons within the cylinders to rotary motion at the wheel.

The right crankpin usually leads the left by 90 degrees on a two-cylinder engine.

There is a relief valve on the front of the steam cylinder to admit air when the engine is drifting with the throttle shut, otherwise there would be a vacuum or air pressure within as the pistons move constantly when the engine is in motion.

The small curved pipe just visible in the steam above the valve chest carries valve oil from the lubricator in the cab and into the steam supply for lubrication of the piston valve and the piston below.

At each end beneath the cylinder can be seen condensate drains which are opened from the cab with links and levers to drain water from condensed steam from the cylinders before it can accunmulate to a level to stop the piston in it's travel, damaging the cylinder heads or causing other mechanical damage.

Sand Dome

Thanks. I found an explanation of the Sand Dome. That's about the last place I'd have looked for sand.

The Sandpiper

Something tells me the goddam pipe is for sand.

The Pipe

It's GOT to be for sand. Note that both the "fore" and "aft" pipes go up to the same dome, which has a rather loose-looking lever connected to the cab by a rod (that is ALWAYS slightly bent in these pictures). So the "after" pipe is for those times when the engine must BACK UP on slick rails. Just makes you marvel, at driving wheels tall as a man, and the double-barrel compound cylinders (first the high pressure steam, than rather than wasting the residual pressure, let it work again in a low pressure cylinder). To the true locomotive experts out there - how does the sand get INTO the dome?

What's the pipe

the pipe behind the left driving wheel is for sand, but when the loco is running backwards. if you look on the right had side just infornt of the mans leg you will see the same thing and that is for sanding going forwards.

Backwards sanding

You would sand behind the driver if you needed traction when starting in reverse. Both pipes are coming from the sand dome.

What's the pipe x2

A similar pipe hangs down in front of the other driver, right by the guy's left leg. Both seem to originate from the bell shaped thing on top.

Sand Gets in your Eyes, and Elsewhere.

The pipe behind the rear driver IS for sand, when backing up.

These high-wheeled engines were very slippery when starting and when the engine brake was applied.

A sliding wheel, as opposed to a spinning wheel, will develop a flat spot very quickly, which can damage the rail each time it goes around.

Without sand the Engineer might not be able to start a train at some locations, especially if the rail was wet or greasy.

Modern Diesel locomotives still use sand applied in front of the leading wheels for traction.

If too much sand is applied when not necessary, the locomotive will run out of sand and have none when it is really needed.

Sand also blows back along the train, getting into parts where it is not desired and mixes with grease or oil, and, into the eyes of patrons on passenger trains without air conditioning, the windows being open.

Some streetcars had sanders, the sand being in bins under the seats which folded up to fill the hoppers from within the car.

Sand it is!

The two diagonal pipes coming from the "sand box" (first dome behind the bell) carry sand to the drivers when needed. The engineer can operate a three-way valve for forward-off-reverse sand application. You can see small air lines to the sander valve which run under the jacket. Sand would be applied automatically on an emergency brake application. I am more curious about the lever arrangement to the sand box.

The sand had to be perfectly dry to flow through the pipes. Was this lever used to break up clumps of sand in the box? One good question deserves another!

I think sand is the correct answer.

An identical pipe runs down the side of the engine to just in front of the forward driver wheel, and both pipes originate from the same dome on top of the engine. Sand is the most likely explanation.

My best guess as to why they would have pipes on both sides of the driver wheels would be to provide traction while the engine runs in reverse.

Sander

Anonymous, your first thought was right. The pipe behind the rear driver is to deposit sand on the rails during backing moves. There's another sand pipe ahead of the front driver. Both pipes lead from the sand dome atop the boiler, and you can also see the control linkage that allowed the crew in the cab to apply sand when needed for traction.

Reverse gear

I believe it's a sand pipe for going in the opposite direction.

What's the pipe?

I believe it was for sand...for backing up.

Re: the pipe

I think sand is probably the right answer, since the pipe would be in front of the wheel when the engine was in reverse.

Note the very similar pipe in front of the other driver wheel.

What's the pipe?

I think the sand pipe behind the wheel is used when going in reverse (??)

The Pipe is a Sand Pipe

Follow the pipe upstream -- it's connected to the sand box, and was used to afford traction when the locomotive was backing up.

Sand Pipe

That is, in fact, a sand pipr behind the rear driver. Note that it comes down from the sand box as does the other pipe in front of the front driver.

Mystery pipe

Considering that the pipe comes from the same location as the pipe that goes to the front driver, and considering that trains can go backward, it's a pretty safe bet that it too is a sand pipe. The sand delivered to the front wheel, when going forward, will still be on the rail by the time the rear wheel gets to it. Same when going in reverse.

Re: What's the pipe?

Notice that there is also an identical pipe ahead of the other driver wheel. Obviously, you might need to sand the track for more traction whether you are pulling or pushing with the engine. Thus, you have sanding pipes on either side of the drive wheels.

As for the pipe

That pipe is a sand dispenser. Think of this way. If the wheels start slipping backward, the sand would be delivered to the right spot to regain traction.

Also, when the train reverses direction, which they did in railroading to improve stopping. Remember the airbrakes took several seconds, up to a minute to get the rearmost car to brake. So you have the front of the train going backward as the rear of the train is still going forward. Kind of results in a lot of steel on steel as the couplers crash against each other.

Traction

Yep, those are sanders. You need them both forward and reverse. From the looks of the tires on those drivers, they were used plenty. (They're called "tires" even though they're metal.) Here's how they change them:

Sand, yes

My guess would be sand, for reversing perhaps? Also since that rear pipe leads up to the same spot the pipe in front of the front drive wheel goes...

Fifty years to go

before the diesel engines outnumbered steam locos.

4-4-2 Atlantic type

Built in 1902 for fast passenger service. A sister locomotive, Detroit Toledo & Ironton #45 (also built in 1902) survives at the Henry Ford Museum.

Safety coupler

Note that the coupler is resting on the pilot deck. It is swung out of the way so that it will not catch an object that on the track. Modern diesels have snow plows that deflect objects that might become lodged under the wheels.

What's the pipe?

What's the pipe just behind the big left driver? My first thought was sand, but you wouldn't sand, behind the wheel. Neither would you vent something wet, like steam, onto the wheel. Anybody know?

On Shorpy:

Today’s Top 5