Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Lofty addition

- In 1912

- Keenan Building

- Six years old

- Taken from the P.J. McArdle Roadway?

- It stood only 47 years

- Three track mind

- Incline to the right

- Reach for the sky, 1912 style

- No clean sweep

- Same Job Title, Same Face

- Sadly Lost

- Beautiful ...

- Where you get your kicks

- Aim High

- Pueblo Revival sisters

- Pueblo Neoclassicism

- Milk Man

- Regional dialect.

- Spielberg's inspiration

- Great Photo

- Loaf Story

- Do you still have the Rakes category?

- Could almost be a scene from the 1957 movie 'Hell Drivers'

- The Wages of Fear.

- Conspicuous by their absence

- Got Milk?

- All that aluminum

- No lefties

- Smoke 'em if you've got 'em

Print Emporium

Hot Lead: 1942

September 1942. "Linotype operators in composing room of the New York Times newspaper." These machines cast lines of type (Linotype) from molten lead prior to their assembly by compositors into the printing plates that go on the presses. Photo by Marjory Collins for the Office of War Information. View full size.

Fascinating technology

A few years ago, I found an interesting (to me, anyhow) educational film on youtube showing how a linotype machine worked. I was quite impressed by the gizmo that sorted the letter matrices back into the magazine after they had been used to generate a slug.

Link: http://youtu.be/6wHiddZOfa8

They aren't that noisy

and I still operate one almost every week. I have been doing so for 50 years. I have handled the lead alloy in proper conditions, and my last test showed NO exposure to lead.

Clackity Clackity

In the 1960's and 1970's, my parents operated a small letterpress printing company as a retirement business. Through use the slugs would wear down. So, when we needed replacements or needed copy set for a new job, I would take them to the company we used in the Caxton Building (get it?) in downtown Cleveland (the building was specifically constructed for printing industry firms. It had extra thick concrete floors to support the weight of presses, etc.). Anyhow, each customer had a "lead" account. The weight of returned slugs and outgoing slugs was tallied. The object was to keep the account reasonably close to zero. If you owed too much lead, they insisted some be returned in exchange for continuing to fill new orders. A room full of these operating machines made its own distinctive metallic music: the small metal pieces traveling from their spot in the magazine down to where the slug was cast, and then being whisked back to the top of the magazine, where they self sorted and fell back into the correct holding spots. Molten lead and a typewriter keyboard in one machine - they are amazing! And you never forget the smell of molten lead.

Pin Ups

Anybody notice the photos of FDR and Gen. MacArthur on the wall (top/center of photo)?

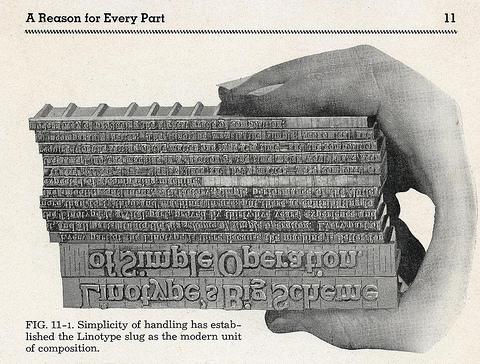

slugs

Here's some of the finished product ("slugs") from a Lino. Then they would be locked up in a form (on a reeaalllyy flat table) to make a "plate" for the press. Lino operators, correct/augment where needed!

California Job Case

Ah, memories of long ago. Junior High School 43 Manhattan, N.Y. It was 1940 and I was 13 years old. We had a printing Class once a week. Real printing presses, real ink and, most of all, California Job Cases. We were taught to set type by hand, operate a printing press and learned the origin of the terms Upper and Lower Case Letters. Ten minutes before the class ended, all the kids had to put the PI (Mixed type) back into their correct compartments. We then tried to clean the ink from our hands before the next class.

Air quality?

from http://www.ncbi.nlm.nih.gov/pubmed/9334482

"Twenty of 38 workers of a printing press were studied. ... The environmental lead in the linotype room was 25% over the accepted values. Twelve of the 20 workers were poisoned and three were highly exposed. Poisoned workers were working in areas with high environmental lead concentrations, were in direct contact with the metal, had plasma lead concentrations over 70 micrograms/dl and an average exposure time of over 17 years." But that was in Chile.

Even

after thirty years working with linotypes i am still amazed at how they worked.

From One Behemoth System to Another

I was in the newspaper business in the last days of Linotype and through the transition to electronic typesetting. These old machines were large and noisy, but some components of the early days of computerized electronic typesetting would dwarf them.

When I first used electronic typesetting, the computer terminals were tied to a mainframe computer where those of us who were editors could edit copy before it went to final plate-making.

The copy we worked from had been typed by reporters on special forms requiring a very specific format of typing. Those typed forms were then fed into a scanner that filled a room the equivalent of a two-story six-car garage. Any errors by the reporter ended up in the scanned data.

Once all the text and photos were scanned by that huge machine, it was a very tedious job with no WYSIWYG in sight to code all that data into page layout. Amid all that visually-confusing code, it was too common to miss typos.

Truly, I missed Linotype and the old pasteup and lithographic plate-making process that seemed simpler by comparison.

Thank goodness for desktop computers and publishing software for making the process less unwieldy.

Vintage insight

In the late 1980s I was on a service call in a printing company on a Saturday. The firm had one of the last Linotype machines in active use. I had the privilege of observing this supremely complex machine in operation for ≈ 45 minutes. One thought kept crossing my gear-head mind:

Ottmar Mergenthaler's opium dream. fwiw, an OSHA inspector was monitoring the lead vapor content of the air in the machine's vicinity. Sic transit gloria mundi.

Hot metal to cold type

Worked for Mergenthaler Linotype in the late 70s early 80s.

While there we converted the NY Daily News from hot metal to a phototypesetter based editorial and classified system.

Remember walking around the typesetting area with dozens of the old behemoth machines clanking away.

An odd side effect of the conversion that few expected was that the quality of the product due to spelling, grammar and factual content went down. Seems that beside setting type the operators also acted as proofreaders.

Had them at Lane Tech in 1980

Lane Tech hs in Chicago was still teaching with these in 1980. They also had a Ludlow machine that made headline type out of hot lead. Would love to see a shot of one of those.

Re: etaoin shrdlu

being the 12 most common letters in the English language, in descending order of appearance, seen by me many years ago on the transom of a pricey yacht/cabin cruiser. Guess the owner was in printing or publishing. In earlier pre-Linotype days, when the characters were kept in font cabinets and set up in rack for the presses this order of appearance governed the quantity of these characters and their location in the font drawers and cabinet.

I had to learn to use one of these

I learned to operate a linotype machine in my high school print shop class in the mid-1970s. I admit I was never very good at it, but since this skill very quickly became obsolete, I guess that was no great loss. Now I see these dinosaurs on display in museums ... and boy, do I feel old!

What impressive machines

The printer I use still has one running in the letter press dept. His grandfather started the business in the 1890's and has another seven purchased over the decades in the basement for parts. I've never heard a roomful of them but a single machine is pretty quiet. The Minnesota state fair runs one in a newspaper office demonstration during the fair every year.

Thanks for the memory jog MikeK that the printers jargon for matrices is mats.

Read any magazines?

Each machine has three selectable magazines. They are the large trapezoidal top objects at a 45 degree slant. Each font face, size, and style required a 90 character matrix loaded into a magazine. With three per machine, to have the all the type selections that come with MS Word you would need 500 linotype machines or just one machine and a stack of 1500 loaded magazines and a lot of time and labor to change them out! Needless to say, most periodical publications had their signature font faces and they didn't change much.

Interesting Comment

...about deaf operators of Linotypes, Max. I had never heard that before, but that would explain my deaf uncle's involvement with them. He not only operated one, but in later years, when they were becoming extinct, he would buy old Linotypes and re-sell them. Now I know why!

The Spitoon

The spittoon adds a nice, personal touch to the workplace.

Lead mule for the yearbook

During my 1964-65 stint on the Salesian High School yearbook in Detroit, one of my jobs was to take copy to a local printing company to have the captions for photographs printed via a linotype. In those ancient times each photograph had to be trimmed and pasted on special grid paper with rubber cement and likewise for the printed captions. The teacher in charge of the yearbook operation required that all captions be right and left justified with the edges of the photograph and all lines be of equal length. The linotype could make small adjustments of letter and word spacing, but sometimes one or more rewrites were required to get a perfect fit. At the beginning of the yearbook season I had to take several long bars of linotype lead to the printer. These bars had a hole in one end and where automatically lowered by a chain into a lead melting unit attached to the linotype. I assume the lead was some sort of special alloy and not recycled auto wheel weight lead. I never inquired why the yearbook had its own lead. Perhaps I was a lead mule for the yearbook.

Still in use in the 1970's

I went on a field trip to the Chicago Tribune around 1970 and they were using the same machines as in the picture.

I don't recall it being too noisy.

Wow!

That's a LOT of exposed belts and pulleys in a crowded, noisy space.

Familiar look and smell

I grew up in a small-town newspaper family in the early 1950s, and we had two Linotype machines, operated five or more days every week by any of the four men (all heads of their households) who put together our weekly editions, of perhaps 8 or 12 pages.

These amazingly-engineered machines operated with a hot molten metal smell and some smoke, but they were huge improvements over the hand-set type used previously, letter by letter and piece by piece.

When I left the newspaper business 15 years ago, everything was done silently on color computer screens in bright, clean work spaces. Most of the staff were part-timers, almost none were heads of their households, and they could produce 8 or 12 pages ready to print in a few hours. Then they'd press a button to send the screen image directly to a printing press, perhaps 100 miles away.

But I can still smell that molten metal aroma, and while I don't miss it, I certainly remember it well.

What fun they were

I had the privilege of using one of these in the late '60's while working part time at my Dad's print shop, and they were a hoot to run and work with.

Belts, levers, hot lead, and a host of unique sounds..and it sure beat setting type by hand.

If a Linotype makes a noise and nobody hears it...

Deaf people were found in the ranks of Linotype Operators in greater numbers than many other careers. Many deaf schools offered Linotype training.

I wouldn't be surprised if some operators started to go deaf after they started their careers.

On Shorpy:

Today’s Top 5