Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Baldwin 62303

- Baldwin VO-1000

- Cold

- No expense spared

- Tough Guys

- Lost in Toyland

- And without gloves

- If I were a blindfolded time traveler

- Smoke Consumer Also Cooks

- Oh that stove!

- Possibly still there?

- What?!?

- $100 Reward

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

- Icing Platform?

- Indiana Harbor Belt abides

- Freezing haze

- Corrections (for those who care)

- C&NW at Nelson

- Fallen Flags

- A dangerous job made worse

- Water Stop

Print Emporium

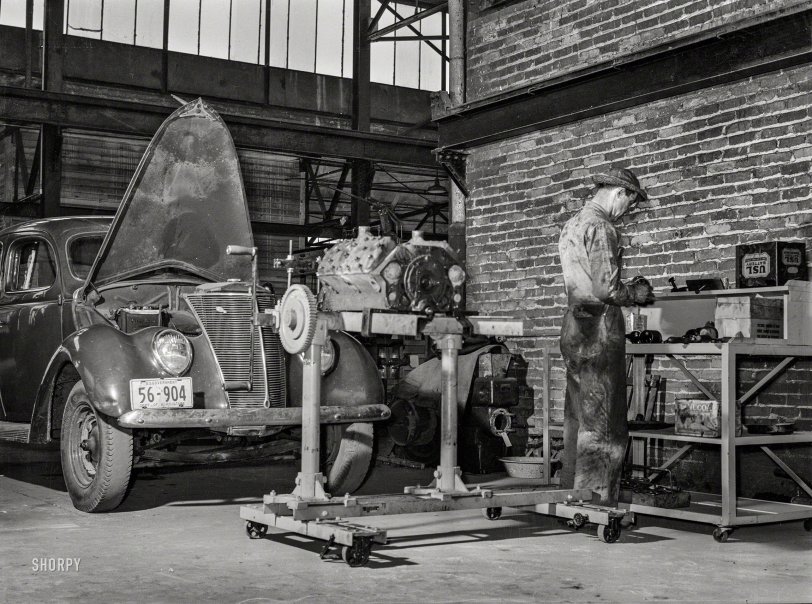

In the Shop: 1939

May 1939. "Repairing automobile motor at the FSA warehouse depot in Atlanta, Georgia." Acetate negative by Marion Post Wolcott for the Farm Security Administration. View full size.

More than just automobile engines

are being repaired here. I see a stationary engine next to the wall with the head removed and a repair tag. I can't tell what type it is, but the cooling hopper has an extension added to hold more water.

The mystery of the pistons

Right where the photo turns to blur for my eyes, I think I see a bare cylinder head stud sticking up at the front of the left head. He may just be doing the sides separately, and the right bank is completed or not yet begun. There are certainly no more than four pistons on the bench. The left head is in place, with my guess being that the photographer requested symmetry and less jagged detail right there, and they dropped it back on its studs to make him happy!!

[The him was a her, and I doubt it. - Dave]

Look the other way!

The engine stand is fully rotatable and adaptable to the crazy variety of engines around then!

The Ford there is set up here to rotate around 90 degrees to the center of its axis, but since it is a very compact engine it could also attach 90 degrees to that and rotate on its crank axis. The big crank handle and gear motivate the rotation, and the two rails beside the engine hold the engine. This general sort of engine stand was supplied with a large variety of brackets to directly fit popular engines to the rails.

It had to be able to accept huge variations in length, shape and weight. There were nearly all the shapes we have now, large straight sixes, lots of straight eights, and, almost unbelievably, Cadillac made V-16's through 1940.

The long ramp leading up to the mechanic's feet provided the space needed to hold at least most of these, from flat-two Crosleys up to the 16's.

Tired engine

Remember that most roads in the USA in 1937-39 and well after were dirt, maybe dirt and gravel and if in a really well off county they were dirt, gravel with a generous (sometimes) cover of heated tar. And I am pretty sure that an oil bath air filter was standard on all cars meaning copious amounts of dust made its way to the combustion chamber and the the cylinder walls making a great oil and grit very fine scrubbing compound to eat away cylinders. In this case the mechanic is probably only replacing the oil rings on the pistons. Next tear down the heads come off and the cylinders get a 20, 30 or maybe even a 60 thousandths bore, new pistons and rings, at a minimum.

Two years

I drive a 2006 car and change the oil every 3,000 miles (5,000 km here in Canada), but I don’t even bother checking the oil in between visits to the garage. Here is an engine getting yanked for repair after only two years, while my little yellow engine light went on, just the other day, for the first time ever, after 13 years.

Not the one the revenuers use

I see the MayPops are mounted on the front wheels this time. Wouldn't want to go driving around North Georgia on those tires. Too many curves, hills, frog drowner rainstorms, and the dropoff past the berm on most roads is still pretty steep.

Appears that the FSA didn't have a laundry contract for coveralls. That one could likely stand up in the corner when doffed.

Under the hood

I think I see the Shroud Of Atlanta, or maybe the Hood of Atlanta.

Tired

Nice Maypop Onionskin on the front passenger side. And the driver's side not much better.

Re-ring and bearing job?

There's a lot going on here. I see pistons and connecting rods laying on the bench, which makes me think he's replacing piston rings along with rod and crankshaft main bearings. But, the cylinder heads are still on, and I see the nose of the crank sticking out of the front of the block, at the bottom. I'm no flathead Ford expert, but I know that with some engines you can pull the pistons out through the bottom of the cylinders (so you don't have to pull the heads), but I don't imagine it would be easy to get them back in that way, with a ring compressor on them.

I've never seen an engine stand like that - I'm used to the type where you bolt a fixture to the back of the block using the bellhousing bolt holes, with the fixture having a sleeve on the back that fits in a socket on the stand, allowing you to rotate the engine around to get to the oil pan, crank, rods, etc. This one just doesn't look practical.

I also see that the dust cap is missing from the right front brake drum, and the spindle nut with cotter pin are exposed. This will eventually allow dirt, grit, and water into the wheel bearings, causing an early failure.

The right front tire is an Allstate, a brand sold for many years by Sears, along with Allstate-branded batteries and other items. The battery is a Firestone, so it looks like they spread the business around (or it's just expediency, for a car used out in the field, traveling through small towns).

Overhaul already?

That 221 cubic inch flathead V8 is being pulled from a car that's only two years old.

Also interesting to see that the Department of Agriculture had their own fleet maintenance in those days. That has been the purview of the GSA for decades now.

They don't build em like that any more!

That car is at most two years old and already needs engine repairs, the rest of it looks rather beat as well.

Granted it's a Dept of Agriculture vehicle so it probably spent a lot of its time on dirt roads.

On Shorpy:

Today’s Top 5