Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Details, Details

- What's that building to the left of the tower?

- Coal Barges

- Bromo-Seltzer

- Inner harbor

- The Basin

- What a headache!

- Giant stepladder?

- Baldwin 62303

- Baldwin VO-1000

- Cold

- No expense spared

- Tough Guys

- Lost in Toyland

- And without gloves

- If I were a blindfolded time traveler

- Smoke Consumer Also Cooks

- Oh that stove!

- Possibly still there?

- What?!?

- $100 Reward

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

Print Emporium

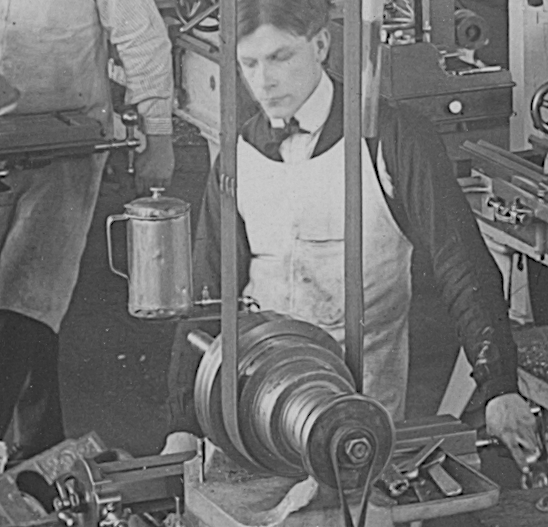

National Cash Register: 1904

Dayton, Ohio, 1904. "Tool room of the National Cash Register Co." A case study in belt-and-pulley power transmission. George R. Lawrence Co. photo. View full size.

Factories lost to the digital revolution

I worked for a tech company in Atlanta that NCR acquired in the mid-1980s. My new manager was in Dayton and would have to travel there often. I remember seeing all these open spaces that were parking lots with no cars. These "lots" were the locations of the factory buildings that created the mechanicals for the cash registers depicted in the photo.

NCR founder John Patterson had experienced some serious quality problems in 1894 (with defective cash registers being returned) at his dimly lit "sweatshops" of the period; to find out why quality tanked, he moved his desk to the factory floor. Didn't take long for him to figure the work environment was terrible. He commissioned architect Frank Andrews to "recast NCR in well-separated, steel framed buildings with walls 80 percent glass," which allowed workers to see what they were doing. Noted landscape architect John Charles Olmsted did the surrounding grounds.

By the late 1960s it was all over for mechanical cash registers. NCR had moved into the digital age in the 1950s, and no longer needed those glass walled buildings of belts, craftsmen and the like; they were summarily demolished leaving nothing but "parking lots."

Fun Fact: Thomas Watson was a sales manager at NCR until he was fired in 1914. He went on to found IBM.

Attached image from "Lost Dayton, Ohio" by Andrew Walsh.

Drip System

This "coffeepot" sure looks like a drip oil setup to me:

"Coffeepots"

They are oil rag containers. Used cleaning rags were stored in them to reduce mess and prevent spontaneous combustion.

What a joyful view for a machinist

There are so many cool things to be seen here, and the tools are all miniature, as would be appropriate for smaller parts.

On the little table in front right is a small (perhaps 3 inch) machinist's vise. It would be clamped down to the T-slots in the table on one of the milling machines using those ears at the bottom.

The first machine front-and-center appears to be a horizontal milling machine, with some kind of power takeoff from the belt drive to run a power cross feed for the table. There is a baby horizontal mill up and to the left with a crossed belt driving what appears to be a similar power cross feed. Modern milling machines use motors to drive their table feeds.

The purpose of a power cross feed is to automatically turn the cranks to move the table in a manner so as to get an even cutting action across the part, leaving a nice finish and easing wear on the machinist's arm.

The "coffee pots" are possibly filled with cutting fluid and dripping coolant onto the part. Either that or the guys kept their coffee handy. This is a job handled today by small pumps and 5-gallon jugs of coolant or a coolant sump.

To the right of the first machine is a bit of the bed and tailstock of a lathe with a fellow assembling a small part.

Behind him is a young looking guy working on the coolest little shaper I have ever seen--I want one of those in my basement. A shaper is a fairly simple tool that pushes a hand-sharpened tool bit across the metal work piece, taking off shavings in a straight line. In this case, the tool moves horizontally, in front of the fellow from his left to right, pushed by the ram--that long cylindrical portion. It typically makes a few dozen strokes per minute, shifting the vise position a little bit over with each stroke. He has his left hand on the height adjustment for his tool bit, which is just above the part in the vise jaws, possibly moving the bit down a few thousandths.

The guy on the front left is working on a surface plate with a height gauge, scribing lines on a part that probably has the old-school equivalent of bluing on it. I believe they used a chemical solution that would leave copper on the part. These days we use Dykem, a stinky paint that comes in red and blue varieties. The purpose of both marking solutions is to dye the part so a scribed line will be sharp and bright.

And you can be sure that all of the hand tools have the owner's name engraved in them. Some things never change.

Toolmaker's Trick

The nearby workers are using micrometers to press parts to the required diameter.

That's my dad

No, it's not literally Dad, but he was a toolmaker for L.G. Balfour for 46 years (1939-85). I visited the tool room a couple times, and it looked much like this.

If you have a college ring, it was probably made by L.G. Balfour.

Teutonic Tap and Die

My wife's people worked at NCR in Dayton for a couple generations. All four of her grandparents worked there at one time or another in the first half of the last century. They were all immigrants: Lithuanian/Prussian and German on her father's side, and her mother's folks were Polish and Hungarian.

I'm not sure what kinds of jobs her great-grandparents had at NCR, but their children ended up in sales and one was a telephone operator. All ended up squarely in the home-owning middle class. Their labor lifted next generation, some with with the help of the GI Bill, to become journalists, managers, and tradesmen.

I ordered a print of this photo for my son, a freshman mechanical engineering student, to hang in his dorm room, in hopes he recognizes the hum of electric motors, the smell of machine oil and the grit of steel filings is in his DNA.

Belt-gium Beer

The Cantillon Brouwerij in Brussels still uses a belt-driven drive shaft to power their mash tun. The belt is adjusted onto the main drive shaft with a wooden paddle. The old ways are sometimes the best ways!

My older brother (whose lovely wife is from Dayton) somehow successfully bid at an auction on a nice extra-large humidor that was once the property of a turn-of-the Century CEO at NCR. Very niiiiiiiice.

Safety First

Studied this very carefully. I don't see glasses or goggles on anyone! I wonder how many eye injuries there were back then. I worked around machine tools for 40 years and wouldn't turn a machine on unless I had my safety glasses on. Just common sense.

I would love to walk through this shop.

Ladies?

Nary a woman to be seen in this photograph! Interesting because NCR was notable for providing special facilities for women as part of their industrial welfare initiatives.

How it works

The face of each pulley is not flat, but has a slight crown at its centerline which causes the belt to stay centered.

A single line shaft next to the windows powers this entire side of the shop. Some of those belts have twists in them, some do not. Those twists in the belts are to reverse the direction of rotation of the driven pulleys above the machines at the right. The long wooden levers hanging from the ceiling near each operator are used to guide the driven end of its belt(s) to idler pulleys to stop the machine, to shift to a larger or smaller pulley to change the speed of the machine, and/or to switch belts to change the machines direction of rotation.

In the 1980s and '90s I was safety director over 26 manufacturing plants, one of which still used the belt-and-pulley system. It actually had the best safety record of the 26. And, yes it was state and OSHA inspected.

Twisted Belts

I believe the reason for the twist in the belt is to make both surfaces wear against the wheel. Makes the belt last longer.

It's a Man's World

Not a woman in sight. They were all busy washing and pressing next day's attire for their men.

Twist

The twist reverses the direction of rotation.

The belts stay on owing to a rounded crown on the pulley. Belts climb towards the high spot. What derails a belt is slippage under load.

Here's a Thought

This entire room full of people were probably replaced by a machine and a couple of folks to watch over it. NCR was at one time one of the largest employers in Dayton. Not anymore. Incidentally, I wouldn't mind having the job of the guy in the suit holding down that table near the middle-left!

Belts Were Twisted

... so that wear could be evenly distributed on both sides of the belt.

Twist in the belts

"Mesmerizing! But I've never understood the logic behind putting a twist into old-fashioned drive belts between pulleys.."

The twist allowed it to run the opposite direction. Depending on how the machine was oriented relative to the overhead drive pulley, it could be easily changed to run in the direction needed.

Twisted belts

I think there are three reasons for the twist in the belts:

1) Untwisted belts tend to flap, and that flapping tends to walk the belt off the pulley

2) Twisted belts even out wear because both sides of the belt are in contact with a pulley instead of only one side

3) There is a little more 'wrap angle', meaning more of the belt is in contact with the pulley

With all that noise

The two most common words spoken would be: Huh? and What?

Neatly attired

The toolmakers of that day and up into perhaps the '50s were dressed up, wearing a tie and the traditional white apron. As hectic as the scene looks, tools are neatly laid out and the area is clean.

Land of the Finger Annihilators

Incredible, every few feet you have numerous belts and pulleys just waiting for an errant finger. I wonder what the injury rate was in factories like this.

What are they?

Ok Shorpy sleuths I see two what look like coffeepots on the two machines in the middle from the bottom up. Looks like more farther up as well. They look like they are floating in the air, no base they are sitting on. What are they, some kind of automatic drip oiler? Hot coffee with no visible means of support? Photoshopped in? Inquiring minds want to know.

Ka-Ching!

Hey, I can see my register beginning to take form—third bench back, on the left.

(Just kidding, it's said to be from the 20s.)

Twist and shout

Mesmerizing! But I've never understood the logic behind putting a twist into old-fashioned drive belts between pulleys, or what kept the belts aligned on the flat pulleys without guide rims. It seems like the slightest imbalance would walk the belts right off the pulleys, resulting in constant delays realigning the belts.

Belt Up

Looking at that, I can see why most of the guys wore bow ties. Even so, it looks as though ties caught in belts, was negated by the aprons.

As a side note, during college I did my internship at NCR Microfilm annex here in Dayton.

My job was to scan salesman expense reports.

Another belt for my friend

That room would drive an OSHA inspector to drink.

On Shorpy:

Today’s Top 5