Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Baldwin 62303

- Baldwin VO-1000

- Cold

- No expense spared

- Tough Guys

- Lost in Toyland

- And without gloves

- If I were a blindfolded time traveler

- Smoke Consumer Also Cooks

- Oh that stove!

- Possibly still there?

- What?!?

- $100 Reward

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

- Icing Platform?

- Indiana Harbor Belt abides

- Freezing haze

- Corrections (for those who care)

- C&NW at Nelson

- Fallen Flags

- A dangerous job made worse

- Water Stop

Print Emporium

Avenging Angels: 1943

February 1943. "Looking up an assembly line at Ford's big Willow Run plant in Michigan, where B-24E (Liberator) bombers are being made in great numbers. The Liberator is capable of operation at high altitudes and over great ranges on precision bombing missions. It has proved itself an excellent performer in the Pacific, Northern Africa, Europe and the Aleutians." 4x5 acetate negative by Howard Hollem for the Office of War Information. View full size.

Keep 'em flying

By mid-1944 Ford's Willow Run assembly plant was producing one B-24 an hour - accounting for half of all B-24s assembled that year. https://www.assemblymag.com/articles/94614-how-fords-willow-run-assembly...

"Dontcha know there's a war on?"

"In 1940 President Roosevelt shocked Congress when he proposed building 50,000 aircraft a year. In 1944 the nation made almost double that number. Ford's massive Willow Run bomber factory alone produced nearly one plane an hour by March 1944."

https://www.nationalww2museum.org/students-teachers/student-resources/re...

Being of German heritage

My grandparents lived in Dresden when these Angels of Death rained down on them. An unnecessary bombing, some would argue a war crime, they escaped with just the clothes on their backs, watching people being burned alive from the phosphorus, seeing architectural Baroque buildings destroyed, and a refugee encampment melted into the ground.

There was no military target there, and it was well known as a place the Allies did not target since there was no real military assets in the city. Out in the suburbs sure, light industry. But not in the places the bombs fell.

What a Ride!

A few years ago, for my birthday, my sister bought me a ride on a B-24 out of Dallas. I was strapped in about where the starboard waist gunner was stationed. Of course, it was very loud and I was surprised at how many gaps there were between the metal structure of the fuselage. At one point I decided to go up front without knowing how tricky it would be to navigate the bomb bay area. I made it through finally. During the flight I was surprised at how much exposed metal there was, which had me thinking that if someone weren't strapped in, any rough turbulence that occurred during a bombing mission might easily have resulted in a concussion, if not worse. All in all, it was worth it and I would gladly do it again. Maybe a B-17 next time, but the ultimate? A co-pilot position in a P-51 Mustang!

Pilot Interview

Link to an interview of WW2 Liberator Pilot who flew 33 missions. There is also a series of flight crew interviews on You Tube by Raymond McFalone. They were done in 2005 when they were about 60 so most have probably passed now.

Ralph Welsh also wrote two books of personal accounts of USAAF veterans.

ineVitable

When you see pics like this made during the War it's quite simply a fact, we were never going to lose this war. The sheer volume and productions numbers alone had to have an impact on the strategy and morale of those Axis powers. We could have churned out these planes for years.

How'd they do that flow chart

This flow chart is part of a collection of Willow Run artifacts at The Henry Ford

The Yankee Air Force is still based at Willow Run and also maintains a museum there.

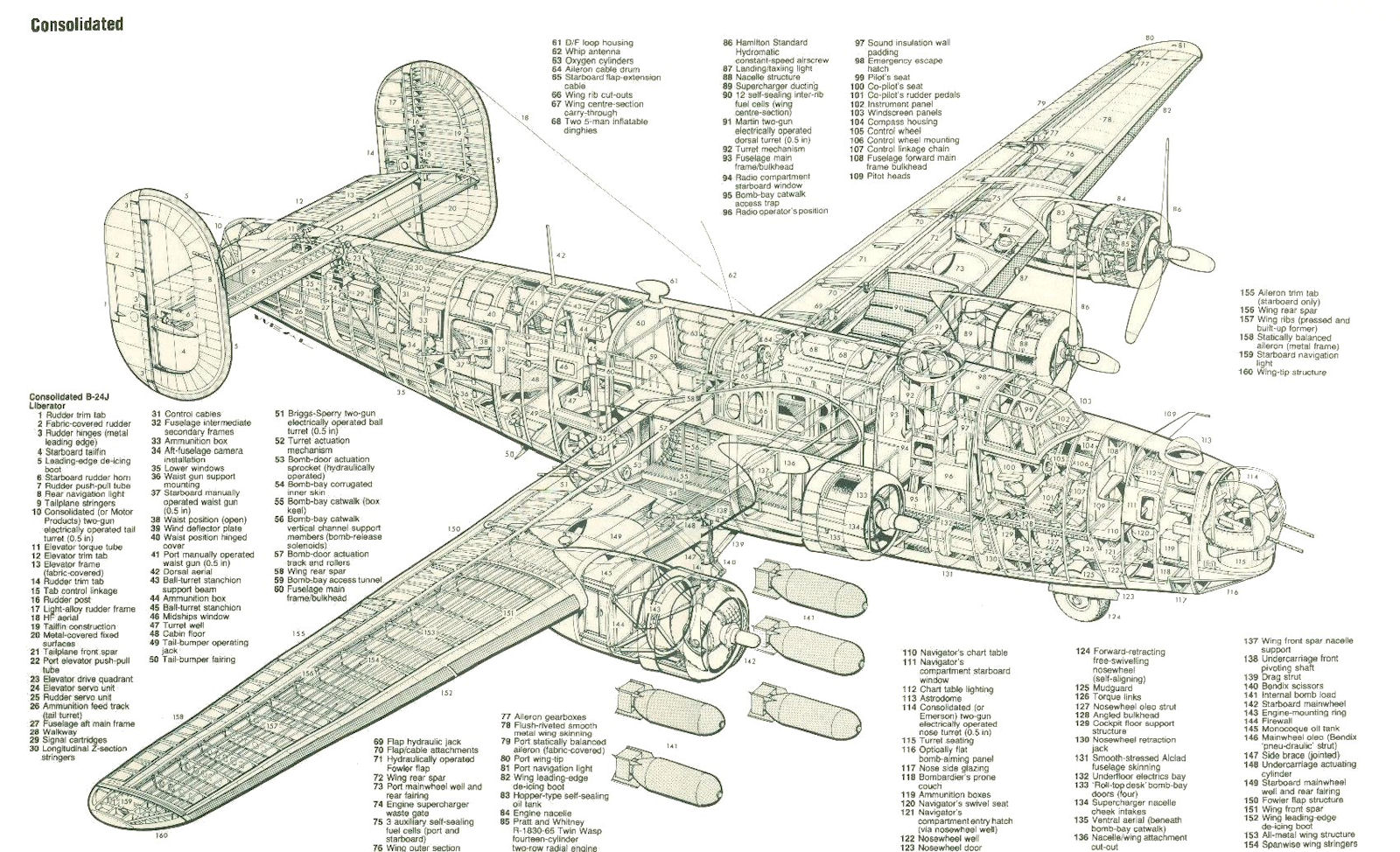

Want to see what a B-24 looks like on the inside?

Click on the link (US Air Force museum website)

https://www.nationalmuseum.af.mil/Visit/Museum-Exhibits/Fact-Sheets/Disp...

Scroll down and click on any of the "Cockpit360 Images"

How the assembly line works

Fortunately, the photo is very high resolution, so it's possible to deduce how these planes are moved and when. The platforms are wired with conduits on the floor, so they don't move. The planes have to be moved into position. The planes in the foreground with full wings attached all appear to be in the same state of construction. A clue is that the same uninstalled fairing piece is visible on top of each horizontal stabilizer. This means that the planes are most likely to be rolled into position between shifts, a whole batch at a time. We see eight planes in these workstations. That's a power of two, so it's a sensible batch size since the stations in the rear are dual column.

Flow chart San Diego And B-24 Cutaway

The Hype

I always wondered why the B-17 got all the hype, pomp and glory while there were 50% more B-24s. Maybe Boeing had the better PR department?

Found photos

While cleaning out my FIL's house, we found some snapshots taken by someone in a B-24 unit. We were able to identify the unit and I actually went to a reunion to see if anyone there could ID the photographer. No joy, but the slice-of-life photos made their way to someone doing a display for a USAF strategic missile unit which had inherited the original B-24 unit's number. I got a nice thank you for sending them, but never did find out who took them (FIL was in the MPs and his service dates don't match up)

The production during WWII was nothing short of an all-out effort, coordinated by the War Production Board. Wikipedia has some details. Can you imagine something like that happening today, with all the bickering and nonsense we're currently experiencing?

13 left

I think I counted 13 B-24s in various states of assembly.

As of 2021, there are only 13 complete B-24s left in the world. Only 2 are still flying. The rest are restored to museum displays.

https://www.airplanes-online.com/b24-liberator-surviving-aircraft.htm

Moving Up

The sections of deck under the outboard side of the inboard engines, where the main landing gear were, were "drawers" that slid in tracks under the outer deck to allow rolling the plane forward to the next station. There is a separate "drawer" ahead of and behind the landing gear, the gap for the landing gear between the drawers is visible. At the left side of the picture foreground, it's where the temporary stairway is placed. It's neat that the decks stepped up to match the slight wing dihedral, maintaining ideal work height.

The selection of Ford was appropriate, as the company understood mass production. The work items would have been divided up between stations so that all airplanes were ready to move up about the same time, with the planes in front moving up first. The timing probably followed Ford's standard practice, where an issue with a work step on a plane meant that the plane would come of the line, then be taken to a rework area to rectify the problem, without holding up the line.

We toured Rouge in the early 50's, and the level of organization at that time was amazing.

The Flying Boxcar

America doesn't win wars, it overwhelms them. The Arsenal of Democracy!

The Arsenal of Democracy

In that very location in 2017 I participated in an attempt to achieve a world record of the "largest gathering of people dressed as Rosie the Riveter."

I was only one small part, but altogether 3,734 of us broke the record.

Several authentic Rosies attended as well, many of whom worked at Willow Run.

Willow Run Story on YouTube

There's an excellent (and VERY detailed) 33 minute long video about the Willow Run plant and the B-24 assembly on YouTube.

https://youtu.be/p2zukteYbGQ

There were

18,482 B-24's made, the most of any combat aircraft ever made in the U.S.

Response to girl power

The unfinished area of the nose you are referring to is just above the navigator's position and is the navigator's observation dome, AKA "astrodome". It was used to enable navigators to obtain fixes on stars when flying at night to establish the latitude over which they were flying.

Construction sequence

It looks like the planes in the background, where they are in two rows rather than one, might be the same model but without the outboard wing sections attached. If so, they maybe assembled the fuselage and main wing sections where they could fit two rows into the assembly space and then moved them forward into a single row and added the wing extensions.

How'd They Do That

How the US produced so much for that war always amazes me.

Looking at this picture makes me wonder how did the assembly process work here? Did each plane get moved up to the next work station after a certain number of assemblies were completed? Coordinating the timing of all that must have been a nightmare.

There was even a song about them.

Broadway, of course.

Enjoy!

https://www.youtube.com/watch?v=2X6EkUQ7DRw

"More bombers to attack with,

More bombers 'til the skies are black with ..."

Walter? Oh, sorry pal.

I know the Willow Run plant employed thousands, but I can't help myself. Every time I see a picture of the Willow Run plant in this era, I look for my grandfather. He worked there throughout the war and after, when Kaiser-Frazer took over the plant. I'm not even sure I would recognize the man I first knew twenty-plus years later, but I still look.

Barely a year after Pearl Harbor

this incredible mobilization of American industrial might was fully underway.

Aunt Betty's 1943 Willow Run ID Card

Aunt Betty's Willow Run ID card was found among her belongings after her passing in 2001. Postwar, she worked for the Detroit Times, then NY Times, then Northwest Airlines. A lifelong career girl, she was well-educated, well-read, well-traveled, and interested in everything except marriage.

Designed in One Night

In the book, "My Forty Years with Ford," Charles Sorensen, Ford's Chief Engineer discussed how this plant came about. During a visit to Consolidated Aircraft's plant in San Diego, it was proposed that Ford gear up to manufacture subassemblies that would be shipped to Consolidated. Sorenson declared they were not interested in such work but were prepared to manufacture the entire plane. Using the principles he had developed designing automobile plants all over the world, Sorensen stayed up all night in his hotel room sketching out the layout that would become the Willow Run plant which was up in running within 18 months.

Next steps

How did the planes move from those positions? Were the elevated racks disassembled and reassembled each time or is there some kind of overhead crane system? Neat photo.

Deceased "Liberator"

There is a young man (James S. King) buried next to my grandfather who was a navigator on a B-24 called "Fickle Finger of Fate". He was killed in a bombing mission over Vienna, Austria on Oct 13, 1944. He was 23 years old. I try to decorate his grave every Memorial Day.

https://www.findagrave.com/cgi-bin/fg.cgi?page=gr&GSln=King&GSfn=James&G...

Girl power

Rosie peeking up from a hole (someone who knows the correct name for that, please correct me) near the nose of the first plane is pretty cool. Rosie II, wearing fancy shoes with her overalls, inspecting something just to Rosie I's left. We can do it!

This is What Won the War

Obviously, there were many, many factors that went into the Allied victory in WWII, but I think most historians agree that it was America's vast industrial capabilities, which allowed us to churn out bombers, fighters, tanks, ships, Jeeps, etc., by the tens of thousands that ultimately won the war.

Rosie the Riveter

Looks like a Rosie the Riveter working on the platform on the right on the plane in the foreground. Her shoes don't seem appropriate for an assembly line, but shoes were probably in short supply in 1943.

On Shorpy:

Today’s Top 5