Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Baldwin 62303

- Baldwin VO-1000

- Cold

- No expense spared

- Tough Guys

- Lost in Toyland

- And without gloves

- If I were a blindfolded time traveler

- Smoke Consumer Also Cooks

- Oh that stove!

- Possibly still there?

- What?!?

- $100 Reward

- Freeze Frame

- Texas Flyer wanted

- Just a Year Too Soon

- WWII -- Replacing men with women at the railroad crossing.

- Yes, Icing

- You kids drive me nuts!

- NOT An Easy Job

- I wonder

- Just add window boxes

- Icing Platform?

- Indiana Harbor Belt abides

- Freezing haze

- Corrections (for those who care)

- C&NW at Nelson

- Fallen Flags

- A dangerous job made worse

- Water Stop

Print Emporium

Re-Tire Men: 1929

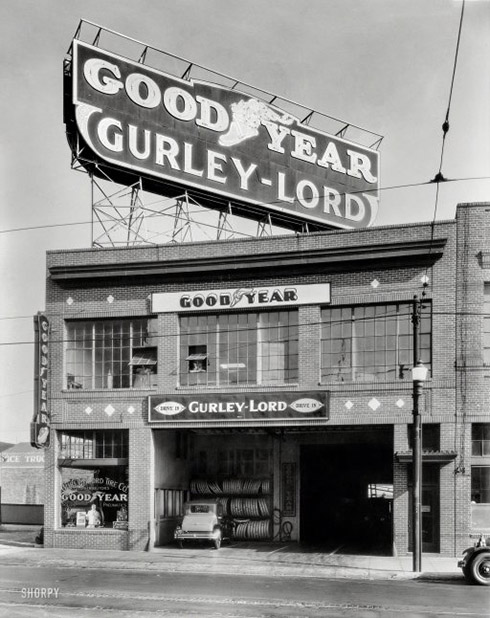

San Francisco circa 1929. "Gurley-Lord tire service station -- vulcanizing molds." The establishment last glimpsed here. 8x10 nitrate negative. View full size.

Retread

My somewhat educated guess is that this is neither a "service station" nor a tire factory. It is probably a retread facility. Retreading was very commonly done on passenger car tires for many years; I believe it is still commonly done on airliner, off-road industrial, and large truck tires because the carcasses of those tires are expensive. Large airplane tires are retreaded many times because of their expense and short tread life. (disclaimer: my knowledge of this topic is from 45 years ago, so maybe wrong today).

[As noted in the caption, we are looking at this place -- the Gurley-Lord garage at 1517 Mission Street. A business where service is performed is a service station. - Dave]

I still remember the smell.

When I was very young a good friend of my father's owned a recapping shop in my hometown. The hot rubber smell from the steam-heated molds is the most distinctive memory. The men buffing the old tread off the tires to be capped left piles of rubber dust, so the place I remember wasn't this clean. The man on the left is inspecting the inside of the tire for a stone bruise or a puncture that could leave a rough spot that would need to be cleaned up and patched. Some of the equipment to repair or inspect tires looks like it came right out of Torquemada's toolbox.

Automotively Exhausting

I watched the jazzy video and was exhausted in that short time! All I could think was how tiring (no pun intended) those workers would be after eight hours of handling those tires!

Video of Machines in Action

These molds would have been used to shape the tires, either to build them up from scratch or perhaps to patch them since this was a service station. The molds would likely have gone into an oven after the rubber and any strengthening elements (e.g., cables or wire mesh) were laid down, tacked together and formed by stretching and spinning the rubber into its final shape.

[The molds themselves are the "ovens." The white covering is asbestos. - Dave]

This video from 1934 shows the whole process at a tire factory:

https://www.youtube.com/watch?v=zXjhV2LEpPo

This video may be from the 1920s and is clearer and much shorter. If you like hot jazz, it's the one to watch. https://www.youtube.com/watch?v=_NgH_8chCog

On Shorpy:

Today’s Top 5