Framed or unframed, desk size to sofa size, printed by us in Arizona and Alabama since 2007. Explore now.

Shorpy is funded by you. Patreon contributors get an ad-free experience.

Learn more.

- Lofty addition

- In 1912

- Keenan Building

- Six years old

- Taken from the P.J. McArdle Roadway?

- It stood only 47 years

- Three track mind

- Incline to the right

- Reach for the sky, 1912 style

- No clean sweep

- Same Job Title, Same Face

- Sadly Lost

- Beautiful ...

- Where you get your kicks

- Aim High

- Pueblo Revival sisters

- Pueblo Neoclassicism

- Milk Man

- Regional dialect.

- Spielberg's inspiration

- Great Photo

- Loaf Story

- Do you still have the Rakes category?

- Could almost be a scene from the 1957 movie 'Hell Drivers'

- The Wages of Fear.

- Conspicuous by their absence

- Got Milk?

- All that aluminum

- No lefties

- Smoke 'em if you've got 'em

Print Emporium

Tumbler: 1910

Cleveland, Ohio, circa 1910. "Rotary coal car unloader." Don't try this at home. 8x10 inch dry plate glass negative, Detroit Publishing Company. View full size.

"Great clouds of coal dust"

Video clip of one of these giant contraptions in use. (Library of Congress)

From Edison films catalog: Shows how a full carload of coal is loaded into a vessel every thirty seconds at the great Erie Railroad docks, Cleveland, Ohio. Great clouds of coal dust rise as each car is unloaded.

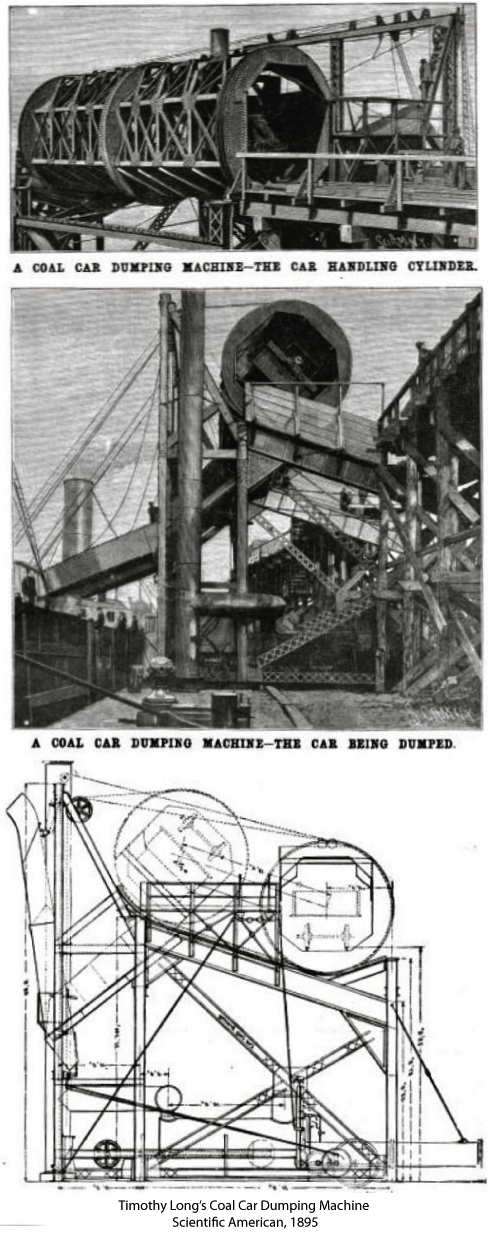

Timothy Long's Coal Dumper

Compared with the previously seen Brown Hoist tipper, this car dumper required the railroad tracks to be elevated significantly above the dock level.

Scientific American, 1895A Coal Car Dumping Machine

Great progress has been made during the past two years in loading and unloading vessels for shipment, and most especially is this true at the lake ports, where it is necessary to handle with great dispatch cargoes of iron ore and coal. The old method, which existed for years, was principally hand work, and the cost of unloading coal by hand was about twenty-five cents a ton. The coal was transferred from cars to vessels by slow working cranes, which could do but little in the course of a day. At many ports there were not even cranes, and wheelbarrows and "navvies" kept a vessel tied many hours at dock when she might have been on her way making something for her owners.

Of the many efforts which have been made to perfect machinery for doing this work, none seem to have met with the success reported of the Long dumping machine, recently perfected in Cleveland by the Excelsior Iron Works Company, and which is shown in the accompanying illustrations.

At a very recent test on the docks of the N. T., P. & O. Railroad in the city of Cleveland, this machine actually made a record of unloading three ordinary railroad coal cars into a vessel in three minutes. The coal was what is known as ordinary lump Massillon, and it was transferred from the cars to the vessel with absolutely no assistance other than the handling of this machine.

The machine is the invention of Mr. Timothy Long, a practical designer who has been connected with the Excelsior Iron Works for a number of years. The car dump consists mainly of a large cylinder, with an inside diameter of 11 feet, and an outside diameter of 16 feet; the length being 40 and the circumference 52 feet. It is set 28 feet above the level of the docks, but on a level with the company's tracks, one of which runs through the cylinder when the latter is at rest. The coal-laden car is set in the cylinder by means of a switching engine; and by the time the car is detached from the train, it is clamped firmly by means of a beam running along the side. This beam acts by hydraulic pressure and the car is held rigid by four iron clamps which fall upon the top of the car's sides, and which are firmly held in place by keys fitting in cogs. These clamps act automatically when the cylinder begins to roll. This clamping process is the work of an instant, and, by means of a lever worked from the end of the cylinder, an engine on the dock level is started. This engine has a cylinder 30 inches in diameter by 19 feet stroke of piston, and a single stroke is all that is necessary to roll the cylinder up an inclined plane into the position shown in one of the engravings, when the coal rolls out compactly into the chute.

When the coal leaves the car, the chutes stand out horizontally, which prevents the coal acquiring any momentum. As soon as the cylinder begins to roll back, the chutes are gently lowered by means of another engine on the dock level, and operated by a man standing between them, until the coal is allowed to pour gently into the hold, the breakage being thus reduced to a minimum, which is something less than when it is handled by being shoveled into buckets and then dumped into the hold by means of "whirlies." Both the cylinder and chutes are operated by means of wire cables, and the operation of the whole machine is so simple as to add greatly to its value, there being no complicated machinery to get out of order. The cylinder is made absolutely accurate in its movements by a series of four inch holes being bored in the perimeter near each end of the cylinder, which fit upon cone shaped pins on the inclined track. This gives all the advantages and none of the disadvantages of a cogwheel arrangement.

The great points in favor of the Long car dumping machine are as follows: The machine operates rapidly; it empties cars of all sizes, in any order, without adjustment being necessary; and the coal breakage is reduced to an absolute minimum. The machine is comparatively cheap as to its first cost, and is economical of operation. The construction, while solid, is not complicated, and can be erected at low cost. Only three men are required. These are the engineer or fireman, a man to operate the cylinder, and a third to operate and control the movements of the chutes. The machine has duplicate boilers, one for use in case of emergency; but the entire apparatus is operated with only 80 pounds of steam. The stoppages usual to any new type of machine have, of course, occurred, but the changes necessary were very trifling in character, and in no way reflected upon the usefulness of the machine.

Interesting Wiring

Yikes! The wiring on the lamp to the right clearly wasn't inspected to today's electrical code. Of course it's a minor hazard compared what might happen if a cable broke on the car unloader.

It May Look Steampunk

It may look like an industrial dead end but this sort of rotary unloader is still popular technology in places where you transfer coal from railcars to ships. The reason is simple enough - with an open hopper car it is quicker to turn the railcar over and empty it that way than to allow the car to drain through the hatches at the bottom of the car. This means you can load more tons per hour and the time the ship is in harbour is minimized. These days you can even empty the hoppers without uncoupling them from the train.

In the days when grain was transported by boxcar a similar technology was used at coast terminals to empty the boxcars, but it wasn't nearly as efficient.

What ingenuity

This one has me itching to dig out my Meccano kit and build a model of it myself.

Unusual design

Most rotary dumpers rotate the car in place and dump into a chute. This one pulls it up an incline until it reaches the chute and empties it. The pegged incline is visible below the men and the operating cables stretch from the wheels at the upper left to the bottom of the cylinder.

Big Light

The lamp at upper right in the picture is so foreshortened, it looks bigger than the men!

On Shorpy:

Today’s Top 5